Securing critical applications worldwide.

Tethers are used in all types of environments and face various operational challenges. They need to withstand everything from severe winds and rain to harsh subsea conditions—all while supporting critical loads and undergoing high stress for long durations. To ensure the optimal solution is always provided, we start by understanding your application and the tether requirements—from length and load, to interface, design-life, and possible coatings or protective jacket needs. For more than two decades, our custom-engineered highly durable designs are ensuring safety, reliability and redundancy for vital operations around the globe.

Subsea

Performance and quality that runs deep.

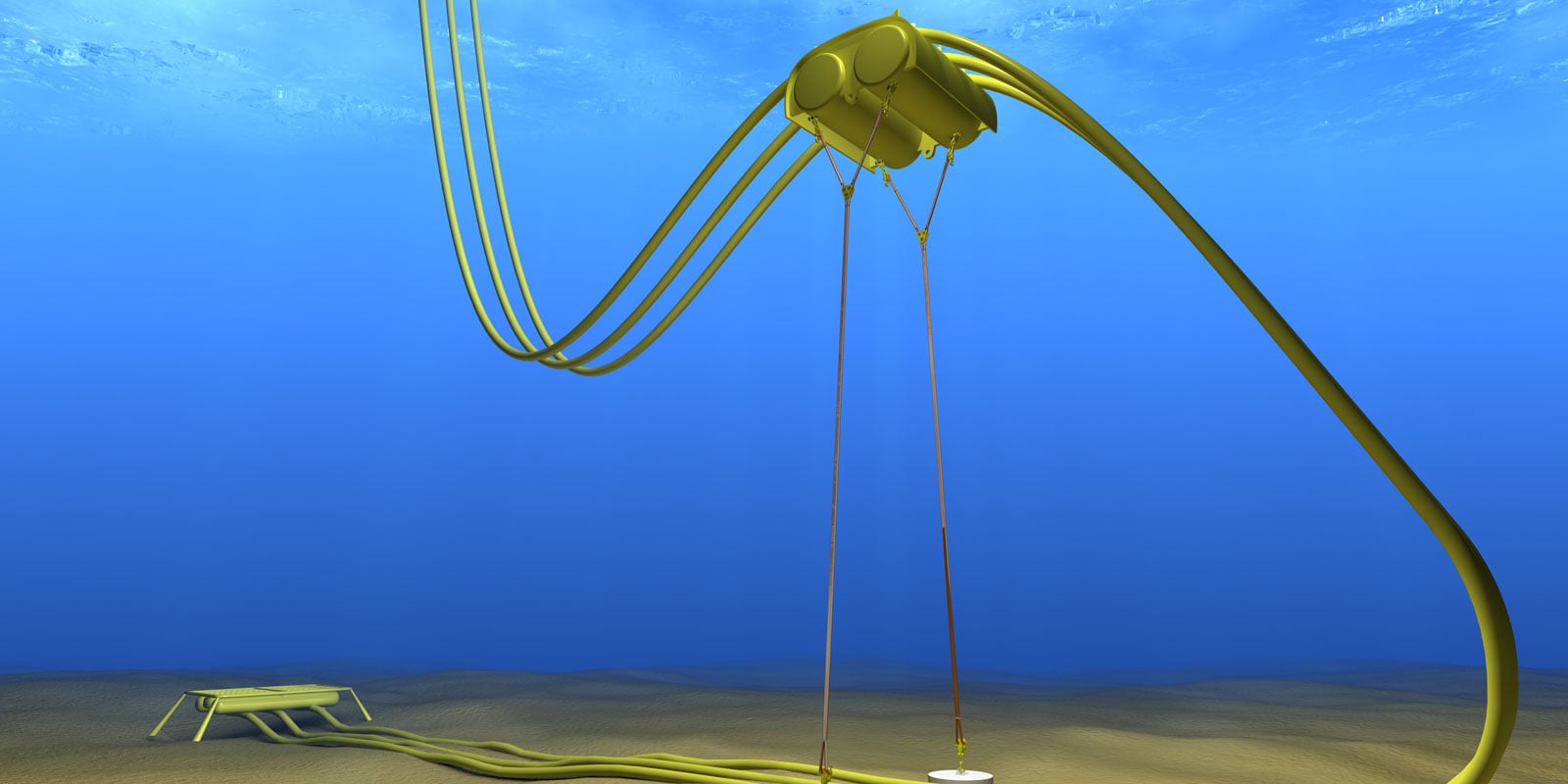

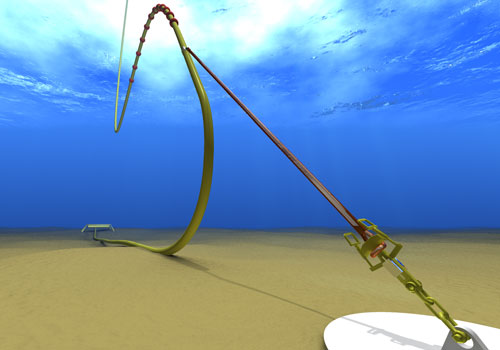

The first Cortland Selantic® synthetic mid-water arch tether was installed in 1996—and that tether is still in use today. Cortland set the industry standard by engineering the first DNV Type Approved Cortland Selantic® tether. Unlike conventional synthetic tethers, the unique construction of Cortland Selantic® tethers enables them to be engineered to extremely tight tolerances and last up to 50 years in the harshest deep-sea environments—standing up to corrosion, marine growth, particle ingress and more. The most highly rated in the world, they’ve been used in the mooring of flexible risers, umbilicals, and Mid-Water Arch (MWA) systems.

Flexible and buoyant, our tethers streamline installation requirements, and integrate with our patented system for ROV-friendly connection. Available as a rope or endless loop sling, each tether is custom-made from high-performance load bearing fibers and protected by an engineered multi-layered jacket. The outer jacket is fluorescent in color for improved subsea visibility.

Install and change out faster with custom hardware.

As subsea technology develops and goes into deeper water, improving the installation method saves significant time and costs. Cortland is constantly developing new hardware items that can interface with tether systems, which are specially designed for ROV installation without the need for costly diver intervention. Examples of custom hardware we design include twin trunnion plates, Cortland Selantic delta plates, Cortland Selantic anchor connectors, as well as other hardware solutions.

These hardware components enable full rotational freedom, and components with an integrated pull-down attachment enable complete tether change-out operations. There is no need for extra pad eyes on the anchor or mid-water arch. Trust our experienced team to design hardware solutions that integrate perfectly with synthetics to maximize efficiencies for your subsea operations.

Benefits of Cortland Selantic® Endless Tethers vs. steel wire or chain

- Significant weight savings

- Lower fabrication, installation, and transportation costs

- Better corrosion and fatigue resistance than steel

- ROV friendly system—easy to install and easy change out of components

- Design Lifetime of up to 50 years

Tensioned Guy Wires

A better way to stabilize free-standing structures.

Synthetic guy wires are non-corrosive and feature excellent dielectric properties. They eliminate electromagnetic interference (EMI), radio frequency interference (RFI), white noise arcing, and other potential interference. Our synthetic guy wires provide significant advantages over steel wires—they broadcast to a broader area, are non-conductive and lightweight for safe and easy handling, and eliminate the need for an insulator. We can engineer extra high strength (EHS) guy cables that are manufactured completely from synthetics, including the terminations.

Lanyards

Lanyards engineered to your exact requirements.

Custom tethers or lanyards can be created to your specifications and application. We’ve engineered lanyards to meet exacting requirements, including capturing a part on an F-16 aircraft. Let’s see what we can do for you.

Standing Rigging

Rig your sailing vessel safely and securely.

Synthetic fiber lines in standing rigging reduces the overall vessel weight. We provide forestays, backstays, and side stays to support the mast on sailing vessels and reinforce against wind loads transferred from the sails. We also design tethers for navy lifelines and can engineer extruded fiber strength members for any rigging application.