Vast engineering expertise for the deepest challenges.

Cortland’s products have been instrumental in improving operational efficiency and safety for the oil & gas market. Our engineered heavy lift slings including Selantic® slings, mid water arch tethers, deepwater deployment and recovery systems, and specialty seismic products are among the highest rated in the world. Up to 86% lighter than steel rope and softer on the hands and surfaces they interface with, synthetic solutions save huge transportation, storage and setup costs. Synthetics are also remarkably durable and will not rust or corrode in salt or freshwater.

With more than four decades of experience, we continue to solve the industry’s toughest operational challenges. From designing a rope heavy enough to sit on the sea floor but light enough for an ROV to manipulate, to engineering lifting solutions for the world’s deepest production sites. We know our customers applications and have an unrivaled understanding of fiber and rope performance behaviors to provide the safest, most effective solution.

Minimize downtime by improving operational efficiencies.

Our engineered solutions make the industry’s most difficult projects possible, while reducing operational costs and risk of injury to put customers at ease. We provide standard offerings, yet any solution can be customized—from release bags and hardware to subsea load-transfer slings and hooks. We also provide the industry’s top-rated Selantic® slings, tethers and hardware.

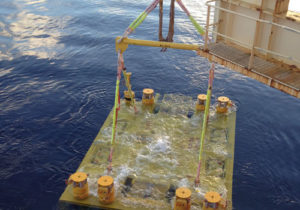

Offshore Lifting Slings

Our engineering team can assist or lead discussions in designing the most appropriate lifting sling solution for superior reliability, durability, and safety.

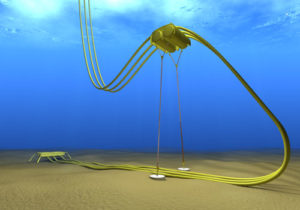

Mid Water Arch (MWA) Tethers

Selantic® tethers from Cortland are among the most highly rated in the world and are often used for mooring MWA systems.

Tugger Winch Ropes

Neutrally buoyant, high-performance fiber rope weighs virtually nothing in water, so regardless of the length of rope used, it does not add anything to the load experienced by the winch.

Sea Fastening Straps

Engineered rope solutions for safely securing cargo during offshore transportation, even in the most extreme sea conditions.

Cable Grips

Minimize any external damage to cables or rope. Cable grips can be used as “quick fit” temporary attachments/tie-off points or as a permanent attachment.